Application fields

VACUUM TECHNIQUE

In order for vacuum systems to provide reliably stable suction performances, the pipe connections must guarantee long-term tightness even at high vacuum. Depending on the medium, LINNEMANN offers the required stainless steel, aluminium or glass components in accordance with standards DIN 28403 ISO 2861 for the KF small flange connections and DIN 28404 ISO 1609 for ISO-K clamping flange connections. Required flexible connections can be supplemented from the hose program. LINNEMANN offers metal hoses as well as hoses with support spirals, which are assembled appropriately and can therefore be integrated safely.

Where disc or ball valves are required for control or for extraction, for example, various systems are available. The mechanically operating vacuum gauges can be used as robust, corrosion-resistant vacuum gauges.

KF Small flange pipe connections and ISO-K Clamping flange pipe connections

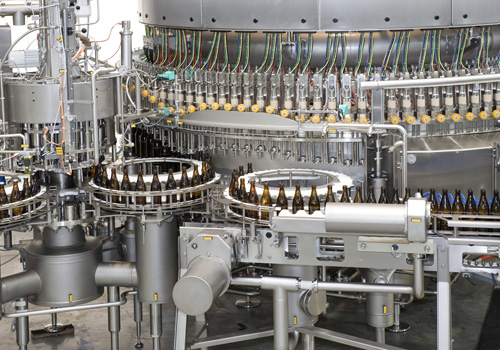

FOOD TECHNIQUE

Since the company was founded, LINNEMANN has placed special value on plant construction with parts that are easy to clean for the food industry. Because special requirements are placed on components that are used in the field of food production, e.g.: the seals used are tested for compliance with the FDA regulations. Corresponding declarations of conformity ensure safety for users. Originally developed for the dairy industry, pipe screwed connections in accordance with DIN 11851 have since become standard in many areas of the food industry as well as the beverages and brewing industry. Clamp connections according to DIN 32676 for the food sector are also offered.

The required pipes are manufactured according to DIN EN 10357 (formerly DIN 11850), and butt weld fittings according to DIN 11852. LINNEMANN stocks a comprehensive range of sizes in DIN, ASME and ISO dimensions, from DN1/4“ up to DN300, in order to connect to pipe diameters that are often different within plants.

Clamp pipe connections

for DIN 32676

STERILE TECHNIQUE

LINNEMANN pipe connections meet the strict requirements of DIN 11853 and DIN 11864 This allows their use under sterile conditions in pharmaceutical and biotechnology facilities.

Depending on the flange type, LINNEMANN offers aseptic pipe screw connections according to DIN 11853-1 and DIN 11864-1, aseptic flange connections according to DIN 11853-2 and DIN 11864-2 as well as aseptic clamp connections according to DIN 11853-3 and DIN 11864-3. Matching hoses are also available according to DIN 11866 and weld fittings according to DIN 11865.

Aseptic flange- and

clamp pipe connections

CHEMICAL TECHNIQUE

For the field of chemical technology, LINNEMANN offers standardised flanges according to DIN EN 1092-1 and ASME B16.5. Furthermore, LINNEMANN has also designed the FLW connection with quick release clamping rings especially for large pipe dimensions from DN300. Another development is the FLY pipe connection in which the seal is located in a rectangular groove where it is protected from the medium. The LINNEMANN GmbH chemical technology product is rounded off by weld fittings according to DIN EN 10253-3, threaded fitting pursuant to DIN EN 10241 and pipes according to ISO 1127.

Welding neck flanges and

clamping rings

BULK MATERIALS TECHNIQUE

In the field of bulk material technology, the LINNEMANN GmbH program contains specially designed, pneumatically operated pinch valves. These are available with a variety of different process connections. The very practical ring grip pipe couplings, which enable easy and safe pipe couplings without the need to weld flanges, are also available for this field of application. The large-radius arcs and other fittings that are required for bulk handling complete the product range.

Pinch valves

and tube couplings