Chemical technique

FLY Clamp pipe connections

The FLY clamp pipe connections were developed by LINNEMANN, are TÜV certified and versatile. They can be used both for gaseous and for liquid media as well as for bulk goods and with high-vacuum processes. Preferential fields of application are chemical, semiconductor, plastic, cosmetics, pharmaceutical, food, and beverage industry.

FLY clamp connections were especially developed by Linnemann to make secure connections in process plants in the chemical industry, the semiconductor, plastic, cosmetic and pharmaceutical industry as well as in the food and beverages industry. Equally in a high vacuum or at overpressure.

The almost return-free or dead space-free construction enables (allows) it to be used in the high vacuum and in the overpressure or high pressure range with media such as gases, liquids and also bulk materials.

The fast connection principle of the FLY clamping ring connections is equally fast and safe. The sealing ring inserted into the groove of a flange is held independently. The stainless steel flange placed against it is therefore force-centred. When the clamps are closed, the flanges are closed so that the end faces are touching smoothly. The D-sealing ring is deformed so that an equally high vacuum-tight and pressure-tight, resistant flange connection is produced.

The program comprises

- Clamping rings TÜV type tested

- Gaskets FDA conform and peroxid cross linked of PTFE-FKM, NBR, EPDM, VMQ, FKM,

- Flages

- Blind flanges

- Imidiate pieces

- Bends

- T-pieces

- Butterfly valves and ball valves

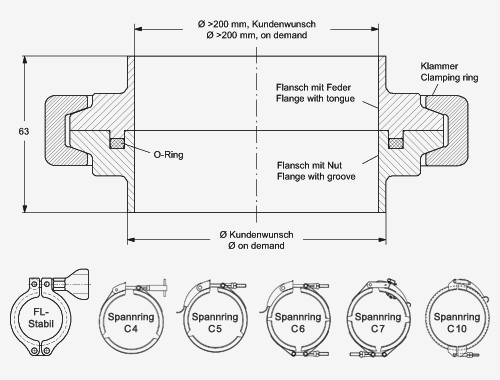

FLW Clamp pipe connections (custom products)

The FLW clamp pipe connections were developed by LINNEMANN and can be used both for liquid and gaseous media as well as for bulk goods. Preferential fields of application are chemical, plastic, cosmetics, pharmaceutical, food, and beverage industry.

The assembly of pipes with large pipe dimensions in plant construction requires special pipe connections. Special designs are expensive. LINNEMANN GmbH in Tübingen therefore offers the FLW pipe connection system. With diameters of 300 mm upwards, rigid or flexible pipes or hoses can be assembled quickly and tightly and separated again if necessary, e.g. for maintenance or cleaning purposes.

Tongue and groove flanges of stainless steel or other materials, appropriate O-rings – also FDA-conform – and clamps form a secure connection at vacuum and overpressure from - 30 °C to + 200 °C. Blind covers are available for terminations. A special feature of this system is the wide range of clamping rings with two-part or multi-part clamp segments.

Safety locks prevent accidental release. An optional, additional, flexible clamping possibility in the area of the joint ensures optimum distribution of the connecting force. The FLW clamp connections are used with abrasive bulk materials or also gases. Typical media are grain in mills, chips in fodder plants, pellets in the plastic industry, mixing components in the production of fertilizers but also fresh air and exhaust air in painting plants and in clean room technology.

The LINNEMANN GmbH delivery scope includes special designs:

- flanges with welded end for pipe inside dimensions Ø 200 – 800 mm

- flange welded end with wall thickness greater than 2 mm

- gaskets in the materials NBR, EPDM, VMQ or on request

- clamping band-clamping rings with clamp segment parts and closure and optionally with swing bolt joint

The desired clamping ring type is produced according to the flange dimension specification according to customer inquiry and the setting possibilities of the clamping band required by the customer.

Welding neck flanges EN 1092-1 + ASME

The flange connections can be used for gaseous and liquids as well as for bulk goods. Preferential fields of application are chemical, foodstuff, beverage, plastic, concrete, mining industries and power plants.

Pre-welded flanges represent a very stable, releasable screwed flange connection for pipes which is used for pressure levels from ND 6 to ND 40 or 150 to 600 lbs. They are therefore used commonly in process plants in the chemical, plastic, cement, mining and power station industries. But they are also used in the food and beverages industry.

In the assembly of the pre-welded flanges, the gasket is positioned between the end faces so that they do not directly touch. Bolts are pushed through the holes in the flanges and locked with nuts. This results in very pressure-resistant and tight hole flange connections.

The LINNEMANN GmbH delivery scope includes flanges, blind flanges and sight glasses of the following DIN standards:

- DIN 2527

- DIN 2631

- DIN 2632

- DIN 2633

- DIN 2633

- DIN 2634

- DIN 2635

Flanges according to EN 1092-1 or ASME B 16.5 are also offered.

DIN and EN flanges are available in sizes DN10 to DN500 or ASME flanges in nominal sizes DN1/2“ to DN12“.

AISI321, AISI 316Ti, AISI 316L, AISI 904L as well as 1.4541, 1.4571, 1.4404, 1.4435 and 1.4539 are available as flange materials.

Fittings for welding DIN 2605, DIN 2615, DIN 2616, DIN 2617

The fittings for welding are used with process engineering facilities with simple requirements for gaseous and liquid media as well as for bulk goods.

Fittings and mouldings for welding in according to DIN serve to provide secure, permanent connections of pipes. They are used in simple industrial applications for gaseous and liquid media. The LINNEMANN GmbH program offers cold-formed welded fittings as a standard. Heat-treated welded fittings can also be provided on request. The surfaces are bare metal and different surface qualities and surface roughness depths are available depending on the production process and on request.

The flange sizes DN10 – DN300 belong to the catalog delivery program:

- Reducing pieces centrica, DIN 2616

- Reducing pieces eccentric, DIN 2616

- Bends 45°, DIN 2605

- Bends 90°, DIN 2605

- T-pieces, DIN 2615

- Bottem convex and caps, DIN 2617

The following stainless steel fittings are also available in the flange dimensions DN350, DN400 and DN500:

- Weld-in reducing pieces

- Weld-in bends, similar to DIN 2619

- Weld-in T-piece

- Clapper floor, DIN 28011

- Saddle ferrule, DIN 2618

Threaded fittings

The threaded fittings are used with process engineering facilities for gaseous and liquid media for easy connection of piping components.

Threaded fittings are used in many process plants for gaseous and liquid media for simple connection of apparatuses and fittings as well as for connecting pipe sections.

The threaded fittings are equipped with Whitworth pipe threads according to DIN 2999 or EN 10266-1. Threaded connections are thread tight because a screw connection of a cylindrical female thread G and a conical male thread R exists. LINNEMANN GmbH offers threaded fittings according to ISO 228-1 and NPT.

The scope of delivery includes the following threaded parts:

- Welding sockets

- Sockets

- Half sockets

- Reducing sockets

- Welding nipples

- Wrench face welding nipple

- Tube nippel

- Tube double nipples

- Double nipples hexagonal

- Reducing nipples hexagonal

- Reducing pieces hexagonal

- Hose nozzles, hexagon, thread

- Hose nozzles, thread

- Hose nozzles for welding

- Plug sqare

- Plug hexagonal

- Screw plug

- Cap hexagonal

- Nuts hexagonal bottom

- Angles

- T-pieces

- Cross pieces