Bulk materials technique

Tube couplings and fittings

The Tube couplings are used especially for conveying systems and production lines with which various bulk goods as grain, flour, granule, powder, dust etc. can be conveyed pneumatically with low pressure or overpressure. Preferential fields of application are the chemical-, pharmaceutical-, plastic-, and food industry.

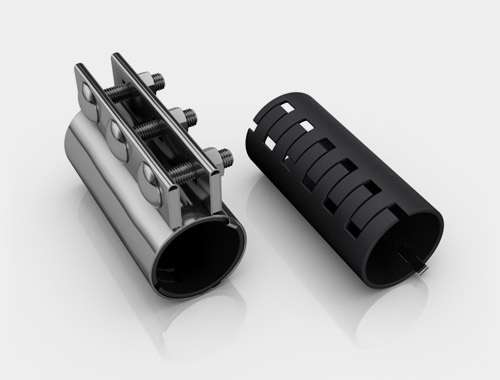

In conveyor systems and production plants which transport bulk materials pneumatically with vacuum pressure and overpressure, metal locking clips with screws are pushed over as sleeves to connect burr-free pipe ends.

This is especially the case in the chemical, pharmaceutical, plastic and food industry where grain, flour, pellets, powder or dust are conveyed.

For pipe outer diameters from DN34 to DN280 LINNEMANN GmbH offers pipe couplings in lightweight and heavy versions either of galvanised steel or stainless steel.

To protect them against pressure surges, the heavy pipe couplings can be reinforced with a locking clip which can be ordered as an accessory.

The prerequisite for a tight connection is that the outer diameter of the pipes to be connected corresponds to the inner diameters of the pipe coupling. The pipe ends are pushed against each other in the connection so that they are positioned in the middle of the pipe couplings.

Before a coupling can be closed by tightening the screws of the clamping rail in assembly, the teeth of the adapter sleeve and the gasket must be offset.

The following fittings are offered in addition to the pipe couplings:

- Pipe bends with large radius

- Branch pieces

- T-pieces

Pinch valves (PV)

The pinch valves can be used for gaseous, liquid, and pasty media as well as for bulk goods, e.g. milk, beer wine, fruit-juice, chocolate, nuts, pulse, mash, feed stuff, varnish,pastes, pills, mud, waste water, dust, ashes, flour, sugar, bran, powder, chips, grain, fertilizer, sand, gravel, concrete and the like. Preferential fields of application are food, beverage, pharmaceutical, cosmetics, chemical, plastic, wood, concrete, and mining industry, purification and power plants.

The area of application of pinch valves covers a large number of branches. Pinch valves control the flow of milk, beer, wine, fruit juices, fodders, pastes, tablets, sludge, waste water and many other media. The area of application covers the food and beverages industry as well as the chemical, pharmaceutical and cosmetic industry accordingly. Pinch valves from LINNEMANN are also used in mining, in sewage plants and in power stations.

Pinch valves are closed by compressed air. The compressed air let into the control pressure chamber presses together the hose sleeve until the valve passage is completely closed. The recoil force of the hose sleeve opens the valve when the pressure drops. This process is supported by the operating pressure of the medium. The sleeves can be delivered FDA-conform depending on the application.

For the pinch sleeves, LINNEMANN GmbH offers a selection list for all available sleeve materials with regard to their material properties such as media suitability, wear resistance and temperature resistance in the online catalog and as a PDF download.

The delivery scope includes:

- pinch valves with welded pipe end

- pinch valves with threaded pipe end

- pinch valves fully assembled with ferrules according to:

- DIN 32676

- DIN 11864-1

- DIN 11864-2

- DIN 11864-3

- DIN 11851

- DIN 2632

- pinch valves with clamp ferrule

- pinch valves with FLY flange DIN

- pinch valves with hygienic threaded ferrule DIN 11853-1

- pinch valves with hygienic flange with notch DIN 11853-2

- pinch valves with hygienic clamp ferrules with notch DIN 11853-3

- pinch valves with threaded ferrules DIN 11851

- pinch valves with tube

- pinch valves with thread DIN 228

- pinch valves with flange DIN 2632

- replacement hose sleeves with inner hose cover